Strainer: Functions, Types, and Applications in Piping Systems

In industrial piping systems, fluid cleanliness plays a crucial role in determining performance and the lifespan of equipment. One of the key components that helps maintain fluid cleanliness is the strainer.

A strainer is a mechanical filtering device installed in a pipeline to capture dirt, scale, solid particles, or foreign materials carried in liquid or gas flow. By using strainers, pumps, valves, and other equipment are protected from potential damage caused by contaminants.

1. Main Functions of a Strainer

Filtering Impurities

Captures solid particles before they reach pumps, compressors, or valves.Protecting Equipment

Prevents damage and extends the service life of industrial components.Improving System Efficiency

Ensures stable flow by preventing clogging.Reducing Maintenance Costs

Minimizes downtime and costly repairs caused by debris buildup.

2. Types of Strainers

Several types of strainers are commonly used in industrial applications:

Y-Strainer

Compact Y-shaped design, suitable for pipelines with limited space.Basket Strainer

Uses a basket-shaped screen, ideal for systems with higher debris volume.T-Strainer

T-shaped design, often used where larger filtration areas are required.Temporary Strainer (Cone/Plate Strainer)

Installed temporarily during commissioning or system testing.

3. Industrial Applications of Strainers

Oil & Gas Industry → Protecting pumps and compressors from solid particles.

Chemical & Petrochemical Sector → Filtering impurities in high-pressure chemical flows.

HVAC Systems → Maintaining the cleanliness of cooling water circulation.

Water & Wastewater Treatment → Removing solid particles from water flow.

Food & Pharmaceutical Industry → Ensuring fluids remain clean and hygienic.

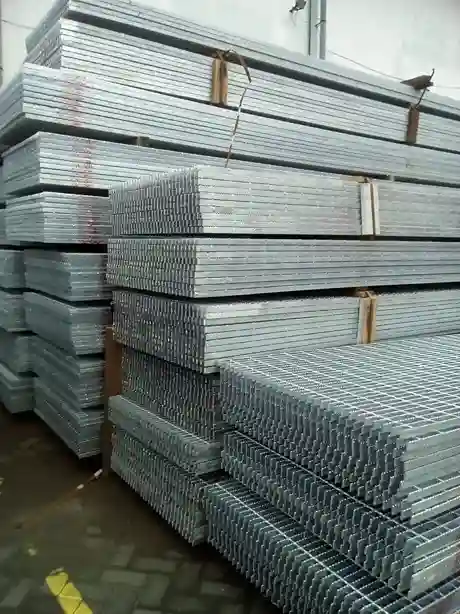

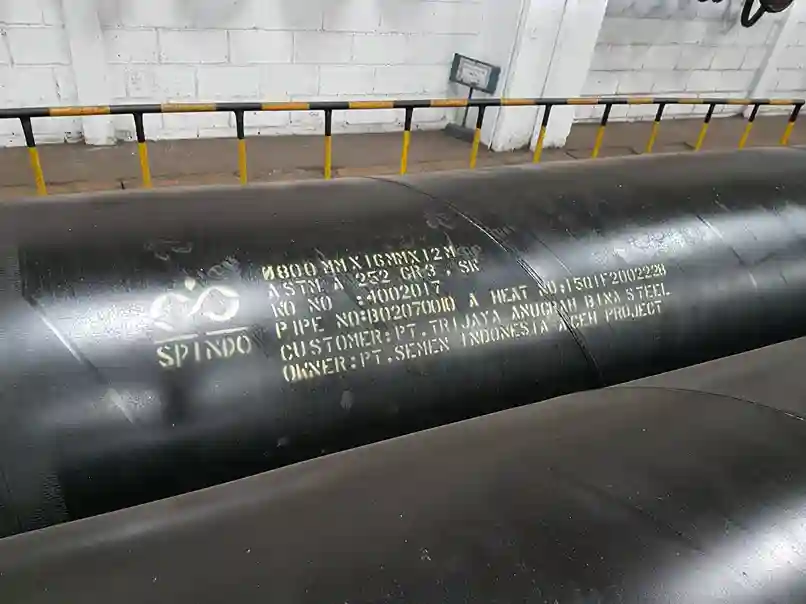

4. Strainers and Piping Materials

The effectiveness of a strainer depends not only on its design but also on the quality of supporting materials such as pipes, flanges, and fittings. To ensure reliable operation, strainers must be installed within systems built with high-quality, pressure-rated materials.

5. TABS – Trusted Supplier of Industrial and Construction Materials

PT Trijaya Anugrah Bina Steel (TABS) is a reliable supplier of industrial and construction materials in Indonesia. We provide complete piping solutions, including:

Steel Pipes (carbon steel, stainless steel, mild steel)

Flanges (PN16, PN40, ANSI, JIS, DIN standards)

Pipe Fittings: elbows, tees, reducers, couplings, and more

Steel Plates & Alloy Materials for heavy-duty applications

With ready stock available in Surabaya, Gresik, and Jakarta, TABS ensures fast delivery and competitive pricing for projects across Indonesia.

Conclusion

A strainer is a vital component in piping systems to protect equipment, improve efficiency, and reduce operational costs. From Y-strainers to basket strainers, the right choice of strainer must match system requirements.

To build reliable piping systems, high-quality supporting materials are essential. Trust TABS as your partner for industrial-grade pipes, flanges, and fittings.

📞 Contact Us:

WhatsApp: +62 812-3083-549

Email: pt.trijayaabs@gmail.com

Instagram: @trijaya_abs

TABS – Your Trusted Source for Piping, Flanges, and Fittings in Indonesia.