Pressure Switch: Functions, Working Principle, and Industrial Applications

In modern industries, maintaining pressure stability is crucial to ensure operational safety and efficiency. One of the key instruments that plays an important role in this process is the pressure switch.

A pressure switch is an electrical device designed to monitor system pressure and activate or deactivate equipment (such as pumps, compressors, or alarms) when the pressure reaches a predetermined limit. With its role as an automatic controller, a pressure switch is widely used in construction, manufacturing, and energy industries.

1. What Is a Pressure Switch?

A pressure switch functions as a pressure-sensitive switch that converts a physical pressure signal into an electrical signal. It operates by using a sensor (diaphragm, piston, or bourdon tube) that responds to pressure changes and triggers a set of electrical contacts.

When pressure exceeds or drops below the set limit, the pressure switch will automatically open or close the electrical circuit.

2. Main Functions of a Pressure Switch

Safety Control

Protects systems from overpressure that may cause leaks, bursts, or accidents.Automation

Helps operate pumps or compressors automatically, turning them on and off as needed.Energy Efficiency

By preventing equipment from running unnecessarily, pressure switches reduce energy consumption and operational costs.Preventive Maintenance

Detects abnormal conditions early, minimizing damage to machines and pipelines.

3. Working Principle of a Pressure Switch

The working process of a pressure switch consists of three main stages:

Sensing Pressure

Pressure from fluid or gas enters the sensor element (diaphragm/piston).Triggering Mechanism

The movement of the sensor changes when pressure reaches the set point.Switching Electrical Contacts

The switch either closes (ON) or opens (OFF), controlling the connected equipment.

For example, in a water pump system, when pressure drops below the minimum, the switch activates the pump. When the maximum pressure is reached, the switch turns it off.

4. Types of Pressure Switches

Several types of pressure switches are commonly used in industries:

Mechanical Pressure Switch

Uses a spring mechanism and diaphragm. Simple, reliable, and widely used.Electronic Pressure Switch

Provides digital output with higher accuracy and programmable settings.Differential Pressure Switch

Measures pressure differences between two points in the system.Vacuum Pressure Switch

Designed for applications requiring monitoring of negative pressure or vacuum.

5. Applications of Pressure Switches in Industry

Pressure switches are widely used in various sectors, such as:

Oil & Gas Industry → Controls pumps, compressors, and pipelines.

Manufacturing → Ensures pneumatic and hydraulic systems run safely.

Construction → Supports heavy equipment requiring stable pressure.

HVAC Systems → Regulates compressors in air conditioning systems.

Water Treatment Plants → Automates pumps for efficient water flow.

6. Pressure Switch and Industrial Materials

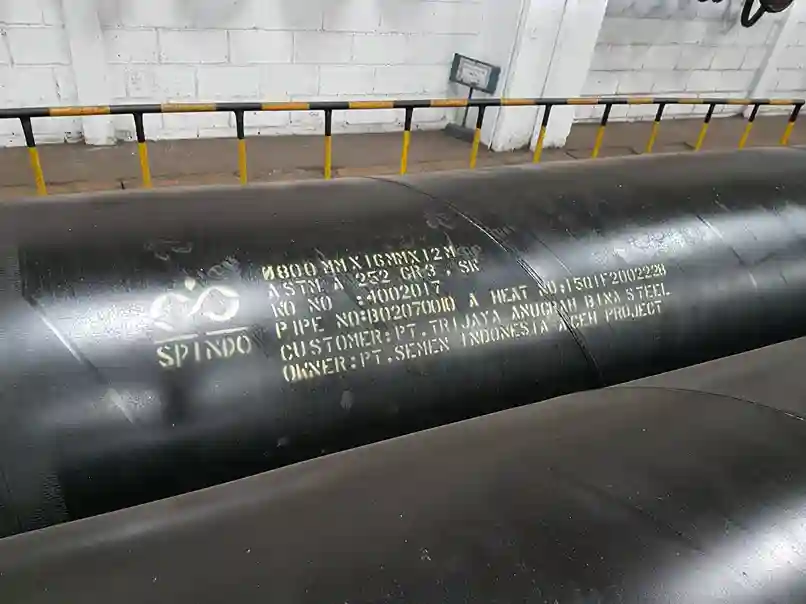

The performance of a pressure switch is closely related to the quality of materials in the system. If pipes, flanges, and fittings used are not durable, even the most advanced pressure switch will not function optimally.

That is why choosing high-quality materials such as carbon steel pipes, stainless steel flanges, and precision fittings is essential to ensure safety and long-term efficiency.

7. TABS – Supporting Industrial Projects with Quality Materials

PT Trijaya Anugrah Bina Steel (TABS) is a trusted supplier of industrial and construction materials in Indonesia. Besides understanding the importance of devices like pressure switches, TABS provides complete stock of supporting materials, including:

Steel Pipes (mild steel, carbon steel, stainless steel)

Flanges (PN16, PN40, ANSI, JIS, DIN standards)

Pipe Fittings: elbows, tees, reducers, couplings, and more

Steel Plates and Alloy Materials for high-pressure systems

With warehouses located in Surabaya, Gresik, and Jakarta, TABS ensures ready stock and fast delivery to support projects across Indonesia.

Conclusion

The pressure switch is a vital instrument that ensures safety, automation, and efficiency in industrial systems. From pumps and compressors to large-scale industrial plants, pressure switches are indispensable.

However, for pressure switches to work optimally, the entire system—from pipes and flanges to fittings—must also meet international standards.

For reliable materials to support your project, choose TABS as your partner.

📞 Contact TABS Today:

WhatsApp: +62 812-3083-549

Email: pt.trijayaabs@gmail.com

Instagram: @trijaya_abs

TABS – Trusted Industrial and Construction Material Supplier in Indonesia.