Types of Flanges for Projects and Factories: A Complete Guide

In construction, industrial, and manufacturing sectors, flanges play a crucial role in piping systems. They connect pipes, valves, fittings, and other equipment, ensuring that the system runs safely and efficiently.

Different types of flanges for projects and factory flanges are designed based on pressure requirements, fluid type, and safety standards.

Here are the most commonly used flanges in projects and industrial plants:

1. Weld Neck Flange

A flange with a long neck welded directly to the pipe.

Advantages: can withstand high pressure and extreme temperatures.

Applications: oil & gas, petrochemical, boilers, large construction projects.

2. Slip-On Flange

A flange that slips over the pipe before being welded.

Advantages: easy installation, more economical.

Applications: factory piping systems and general installations.

3. Blind Flange

A solid flange used to close the end of a pipe.

Advantages: easy to remove for maintenance.

Applications: hydrotest systems, temporary project lines, chemical plants.

4. Socket Weld Flange

A flange with a socket where the pipe is inserted before welding.

Advantages: ideal for small-diameter pipes, withstands high pressure.

Applications: chemical plants, power plants, oil & gas systems.

5. Lap Joint Flange

A flange used with a stub end, making it detachable.

Advantages: practical for systems requiring frequent disassembly.

Applications: pharmaceutical, food & beverage industries, or systems prone to corrosion.

6. Threaded Flange

A flange connected using threads, without welding.

Advantages: suitable for low-pressure systems, quick installation.

Applications: temporary project installations or small factories.

7. Orifice Flange

A special flange with a hole for an orifice plate to measure flow.

Advantages: helps measure fluid flow rate within the system.

Applications: oil & gas, petrochemical, power generation.

Flange Standards for Projects and Factories

To ensure safety and quality, flanges are manufactured under international standards such as:

ASME/ANSI (American Standards)

ASTM (Material Standards)

DIN / JIS (European & Japanese Standards)

The choice of standard depends on project requirements and factory specifications.

TABS: Trusted Flange Supplier for Projects & Factories

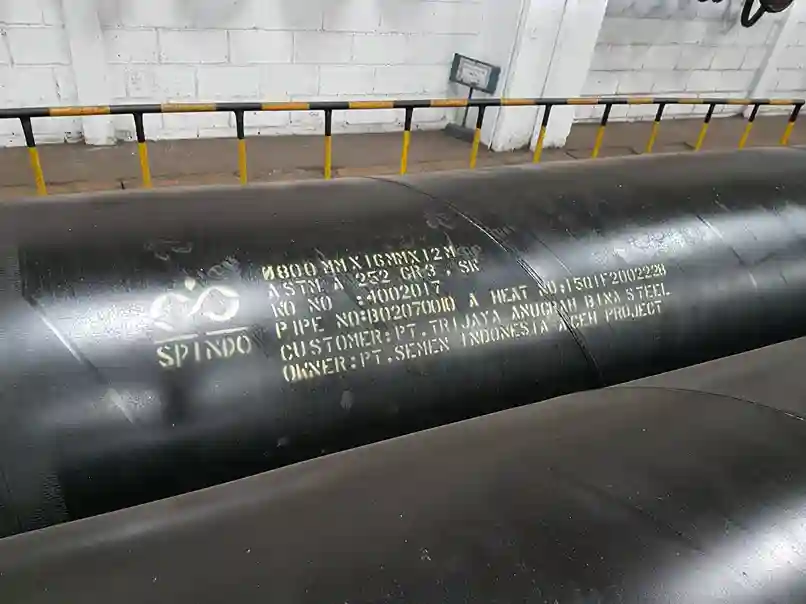

As a trusted steel distributor, PT Trijaya Anugrah Bina Steel (TABS) supplies various types of project flanges and factory flanges with complete specifications:

Weld Neck, Blind, Slip-On, Socket Weld, Lap Joint, Orifice, and Special Flanges.

Materials: Carbon Steel, Stainless Steel, Alloy Steel.

Standards: ASTM / ASME / JIS.

Ready stock at Surabaya & Gresik warehouses.

With years of experience supporting construction projects, oil & gas, and manufacturing industries, TABS is ready to be your reliable partner for flange and steel material supply.

Contact TABS Today

Looking for a flange supplier for your project or factory? Contact TABS for:

✔️ High-quality flanges with international standards

✔️ Ready stock & fast delivery across Indonesia

✔️ Competitive pricing for both small and large-scale needs

📍 Office & Warehouse: Ruko KIG B.9–B10, Gresik – East Java

📞 Phone/WhatsApp: +62 812-3083-549

📧 Email: pt.trijayaabs@gmail.com

🔗 Instagram: @trijaya_abs

TABS – Your trusted flange supplier in Indonesia.