Basket Strainer: Functions, Benefits, and Industrial Applications

In industrial piping systems, protecting equipment from damage caused by debris or contaminants is essential. One of the most effective devices for handling large-scale filtration is the Basket Strainer.

A Basket Strainer is a type of filter installed in pipelines, designed to capture large particles such as rust, stones, and solid debris. Its basket-shaped element provides a larger filtering area compared to a Y-Strainer, making it ideal for high-flow and large-volume applications.

1. Main Functions of Basket Strainer

Filtering Large Debris

Captures coarse particles that could damage pumps, compressors, and valves.Protecting Sensitive Equipment

Ensures machines and instruments run without blockage or contamination.Maintaining System Efficiency

Keeps fluid flow stable and reduces downtime due to maintenance.Supporting Long-Term Reliability

Extends the lifespan of entire piping systems and equipment.

2. Advantages of Basket Strainer

Large Filtration Capacity → Suitable for high-volume pipelines.

Easy Cleaning → Basket can be removed for quick maintenance.

Durable Design → Made from materials such as stainless steel or carbon steel.

High Efficiency → Reduces the frequency of clogging in critical operations.

3. Industrial Applications of Basket Strainer

Basket Strainers are commonly used in industries that require continuous and clean flow, such as:

Oil & Gas Industry → Protecting compressors and process pipelines.

Water Treatment Plants → Filtering sediments before distribution.

Chemical and Petrochemical Industry → Maintaining purity in fluid processes.

Power Plants → Preventing damage to turbines and cooling systems.

4. Basket Strainer and Supporting Materials

For maximum performance, Basket Strainers should be installed with high-quality supporting materials such as:

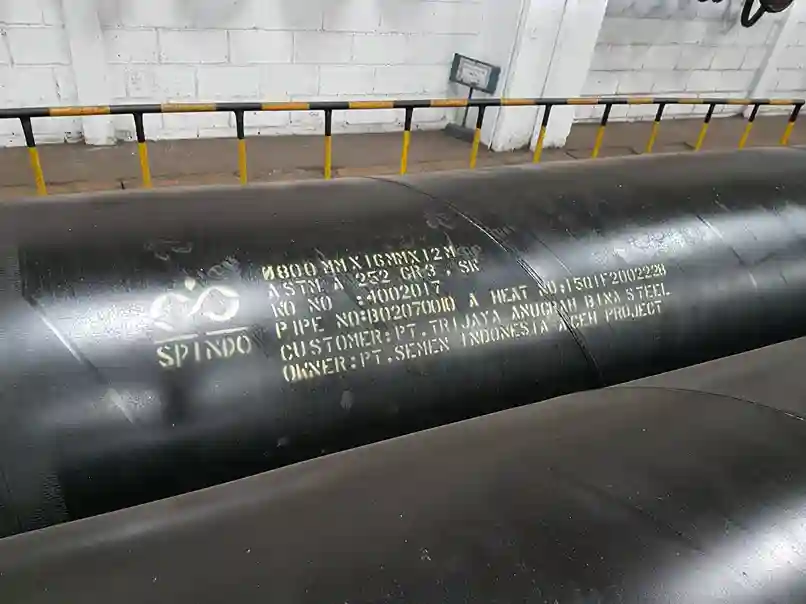

Steel Pipes → for fluid transportation.

Flanges → ensuring strong and leak-free connections.

Pipe Fittings → elbows, tees, reducers, and couplings for system precision.

Alloy and Special Materials → for high-temperature or corrosive environments.

5. TABS – Reliable Supplier for Industrial Piping Solutions

At PT Trijaya Anugrah Bina Steel (TABS), we provide not only strainers but also a complete range of construction and industrial materials including:

Flanges (ANSI, JIS, DIN, PN16, PN40, etc.)

Steel Pipes (carbon, stainless, mild steel)

Pipe Fittings (welded, seamless, custom sizes)

Plates, Round Bars, and Alloy Materials

With ready stock in Surabaya, Gresik, and Jakarta, TABS ensures fast delivery and cost-efficient solutions for your projects.

Conclusion

The Basket Strainer is the right solution for industries requiring high-volume filtration and equipment protection. With its durability, large capacity, and easy maintenance, it is widely chosen for oil & gas, chemical, and water treatment projects.

For reliable strainer installations and supporting materials, choose TABS as your partner.

📞 Contact Us:

WhatsApp: +62 812-3083-549

Email: pt.trijayaabs@gmail.com

Instagram: @trijaya_abs

TABS – Complete Solutions for Strainers, Pipes, Flanges, and Fittings in Indonesia.