Essential Fittings for Safer Construction Systems

In construction and industrial piping systems, one overlooked component can compromise the entire structure. That’s where fittings come in—small in size, but vital in function.

Pipe fittings connect, redirect, or terminate the flow of liquids, gases, or solids through a pipeline. Choosing the right fittings ensures structural integrity, system safety, and operational efficiency—whether you’re building a skyscraper or a refinery.

At [Your Company Name], we supply premium-quality fittings made from durable materials like carbon steel, stainless steel, alloy steel, and more—designed to withstand high pressure, corrosion, and temperature extremes.

Types of Fittings We Offer

Tees and Crosses – To distribute flow

Reducers (Concentric & Eccentric) – To change pipe size

Couplings & Caps – For straight connections and pipe ends

Custom Fittings – Fabricated based on your specifications

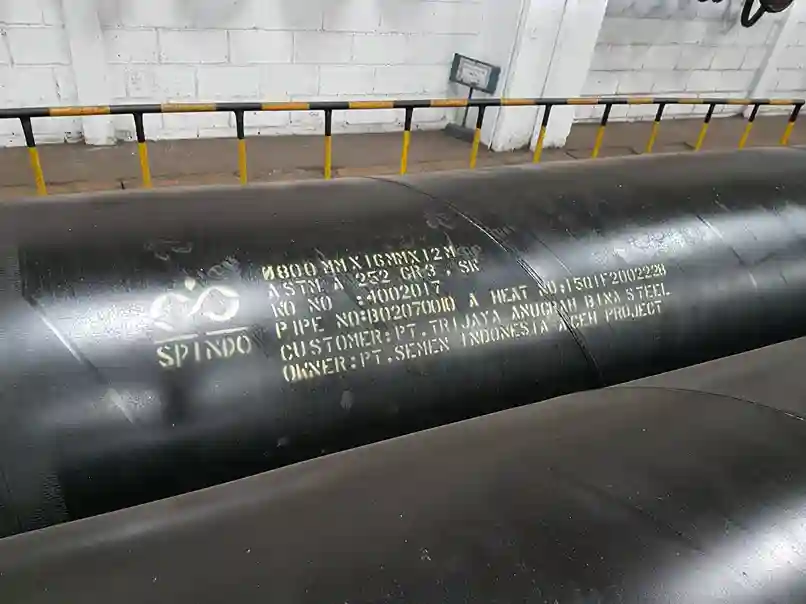

Each fitting is manufactured to international standards like ASME B16.9, B16.11, EN 10253, and comes with full material traceability and certification.

Why Partner with Us?

We serve construction, oil & gas, energy, and manufacturing sectors with:

Bulk supply of standard & custom fittings

Quick delivery & export-ready packaging

Engineering support & drawing reviews

End-to-end support—from procurement to after-sales service

Our fittings have been used in pipelines, chemical plants, offshore platforms, and power facilities—helping clients reduce downtime and improve system reliability.

How to Select the Right Fittings

Choosing the right fitting involves more than size and shape. Here’s what professionals consider:

Material Compatibility: Ensure the fitting material resists the fluids or gases it will carry.

Pressure & Temperature Ratings: Match fittings to system pressure and operating conditions.

Connection Method: Whether you need welded, threaded, or socket-welded types.

Maintenance Accessibility: Choose fittings that allow easy disassembly if needed.

Corrosion Resistance: Especially crucial in marine, chemical, or outdoor applications.

Selecting the wrong fitting can lead to leaks, pressure drops, or even catastrophic failures. That’s why our team is available to consult and support your engineering decisions.

👉 Follow our social media (top-right corner) to stay informed on fittings innovations, technical tips, and exclusive offers!